Leaching: Definition Process Video with Lesson ...

Within the chemical industry, the process of leaching is commonly referred to as extraction. Let''s look at this diagram of how the leaching, or extraction, process works.

WhatsApp)

WhatsApp)

Within the chemical industry, the process of leaching is commonly referred to as extraction. Let''s look at this diagram of how the leaching, or extraction, process works.

Waste slag constitutes a large potential source of chromium contamination of ground waters, particularly under the enhanced leaching action of acid precipitation on waste slag dumps. Numerous investigations into the effect of acid precipitation on vegetation, surface waters, animal life, and stone architecture are to be found in the literature.

Gomes and Pinto (2006) reported leaching of heavy metals from steelmaking slags. Dayioglu et al. (2018) concluded that leaching of heavy and toxic metals from steel slags is largely dependent on ...

suitable conditions for leaching the sulfated slags. Of interest were (1) duration of leaching, (2) amount of leach liquor used (liquidsolid ratio), and (3) type of leach liquor. Slag from smelting test 3 was used. Charge Preparation. Sulfated slag for these leaching tests was prepared in the following manner.

Request PDF on ResearchGate | Chemical and leaching properties of paper mill sludge | Paper mills produce large amounts of paper mill sludge in the treatment of process water. According to ...

Except when stated otherwise, the leaching method below was applied in the majority of the experiments and is the standard leaching method of this work. A 100 g of milled ferromanganese slag was premixed with 100 ml of water. The milled ferromanganese slag slurry was digested in .

via the hot acid leach system, HAL, whereby strong acid is contacted at 160 oC with mineral in a rotary kiln. Figure 1: Namakwa Sands mining operation process overview from the mine to the market place Mine site, Brand se Baai Zirkwa® HAL Wet Dry Mill Mag Roll HTR Zircon Rutile Tiokwa® Smelter Pig iron TiO2 slag Export internationally

American Chemical Society: Chemistry for Life. In the report, Ana AndrÉs and colleagues note that steel mills around the world produce vast quantities of waste dust each year — 8 million – 12 million tons in the United States, for instance, and 700,000 tons in the European Union countries.

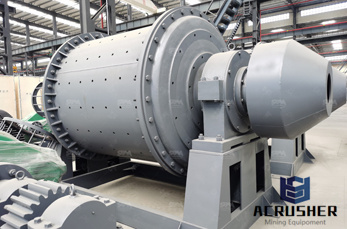

important metals found in tin slag has successfully been extracted using leaching and electrothermal method. The tin slag was crushed and ground to very fine particle sizes of nanometer level using laboratory ball mill, piston and mortar. The particles were .

To enhance general understanding of the physical and chemical characteristics of this material, slag samples from 58 active mills with blast furnaces, basic oxygen furnaces, and/or electric arc .

Physical and Chemical Characteristics of Blast Furnace, Basic Oxygen Furnace, and Electric Arc Furnace Steel Industry Slags. ... The following is a brief description of Blast Furnace Slag chemistry and the phenomenon of leaching as it relates to this material. view document.

Steel slag is a byproduct of the steelmaking and steel refining processes. This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF) steelmaking, electricarcfurnace (EAF) steelmaking, and ladlefurnace steel refining processes. The mineralogical and morphological properties of BOF and electricarcfurnaceladle [EAF(L)] slag ...

Xray fluorescence (XRF) was used to acquire chemical composition of the slag. Leaching test was performed in accordance with EN 124571:20002 (European Standard) to evaluate the mobility of potentially heavy metal elements (Cd, Cr, Cu, Mn, Pb and Zn) in the slag by using tap and rain water as leaching mediums.

A novel hydrometallurgical method was developed to selectively extract base metal values, such as cobalt, zinc, and copper from copper smelter slag at atmospheric pressure. It involves leaching with sulfuric acid and sodium chlorate oxidant and neutralization with calcium hydroxide for better and faster filtration of the precipitate.

materials also influence the chemical composition of local urban runoff. These include extensive exposed cement surfaces, which can leach alkaline calcium salts. Steel mill slags are frequently utilized as aggregates in cement and bituminous asphalt construction. A commonly used alternative to slag for fills and aggregate in the area is crushed

General Kinematics VIBRADRUM® Grinding Mills are proven in dozens of milling applications in the mining and mineral industries.. Each grinding mill is achieving impressive energy savings (3550%), thanks to a unique rotational material motion that is more efficient than conventional ball or rotary grinding mills. New processes such as micron grinding and mechanochemical grinding give our ...

properties of steel slag. Leaching of metals from steel slag has also been studied (Fallman et al. 2000, Apul et al. 2005, Gomes and Pinto 2006, Huijgen and Comans 2006, Mayes et al. 2008, De Windt et al. 2011). However, there is a lack of information on the flow of steel slag leachate through natural soils.

metals, the technological sample of Waelz slag was taken from different places of wastes accumulations. Then, this technological sample was crushed in a ball mill. Chemical analysis verified above mentioned content of main components and content of precious metals .

As the slag is channeled out of the furnace, water is poured over it. This rapid cooling, often from a temperature of around 2,600 °F (1,430 °C), is the start of the granulating process. This process causes several chemical reactions to take place within the slag, .

Leaching (chemistry) 27 · Leaching is the process of extracting substances from a solid by dissolving them in a liquid, the chemical processing industry, leaching has a variety of commercial applications, including separation of metal from ore using acid, .

Leaching is the process of extracting substances from a solid by dissolving them in a liquid, the chemical processing industry, leaching has a variety of commercial applications, including separation of metal from ore using acid, and sugar from sugar beets using hot also occurs on its own in nature; for example substances leaching from plants due to rain, dew, mist ...

Selective leaching and chemical precipitation were adopted to recover P from the normal steelmaking slag. The effects of the acid, pH, and valence of Fe in slag on the leaching characteristics of P were first investigated. The P precipitation in the leachate and the characteristics of the .

Roughly BOF slag, EAF slag and SMP slag can be defined as steel slags. Reviewing the past, utilization of ironmaking slag has a long history. The broken slag from ironmaking was already REUTER, M., XIAO, Y., and BOIN, U. Recycling and environmental issues of metallurgical slags and salt fluxes. VII International Conference on Molten

slag wet ball mill typically; slag ball mill recycling crushing india; ... of a kind used for the extraction of arsenic or those metals or for the manufacture of their chemical compounds, are to be classified in subheading ... Thus, copper and iron extractions were % and %, respectively, when leaching the slag with 3 M H as the ...

WhatsApp)

WhatsApp)