Ultra Performance End Mills Supermill LLC

Supermill brings you the highest performance end mills with geometries and coatings that support extreme cutting capabilities and extended tool life. We call it Ultra Performance!

WhatsApp)

WhatsApp)

Supermill brings you the highest performance end mills with geometries and coatings that support extreme cutting capabilities and extended tool life. We call it Ultra Performance!

Sep 26, 2019· A sand mill is a piece of industrial equipment designed to grind a given material into very small particles of roughly equal size. Sand mills are used for processing a wide variety of products, and can also be used as mixers and dispersants, creating a uniform mixture of several components during the grinding process.

Ball Mill Quarry Browse content from Ball Mill Quarry using the tabs below.

Cleaning and Storing of Ball Mill Charge after the Bond Work Index Procedure is done: Add about 500 g of silica sand into the mill containing the ball charge. Seal the mill. Rotate for 20 revolutions to clean. Empty the mill charge and sand into the ball try once grinding is complete. Clean out the mill using a brush. Put the lid on the mill.

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill,Ultrafine Mill,Raymond Mill From China page is about the grinding mill,includes micro powder mill,high pressure mill,ygm model,raymond mill,3r,4r,5r,6r and ball mills,if you want to buy these joyal grinding mills.

A ball mill is a type of size reduction machine used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

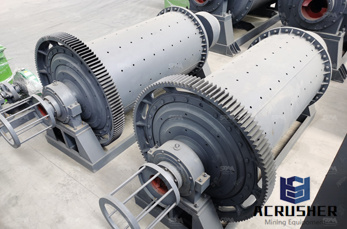

A brief introduction of ball mill The ball mill is the key equipment after the stone or ore materials has been crushed. This type of grinding machine is equipped with a certain number of steel balls as grinding media in its cylinder.

Jan 16, 2018· If you print this Thing and display it in public proudly give attribution by and displaying this tag. This ball mill was made for grinding sand and cleaning objects like rusty bolts. It works but takes a very long time to grind sand down, this is because of the size of the balls are too ...

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

The classifier delivered 33 T. of sand per hour. The total ballmill feed was therefore T. per hr. or 550 per cent, of the original feed. Two Stage Grinding. The object of these tests was to determine the capacity of ballmills when crushing in two stages. The conditions of the test were as follows: First Stage of Ball Milling

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

Ball Mill. SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

Energy Saving Ceramic Lined Ball Mill Silica Sand Ball Milling Machine. Energy Saving Ceramic Lined Ball Mill Silica Sand Ball Milling Machine: Low Cost Batch Type Ceramic Ball Mill With Alumina Porcelain Liner: Industrial Aluminum Ceramic Ball Mill Machine T/H Capacity Ball Load:

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Oct 12, 2017· Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting. This commutation is an essential part of many processes. Various kinds of mills are there with which different material processing takes place.

We believe in delivering only highquality products . For us, customer satisfaction is everything. Hence, we make sure that we test all our ball mills for mineral plants with several minerals like, alumina, barite, zircon sand, dolomite, calcium carbonate, iron slag etc. so that you get the best ball mills USA which is capable of performing all the tasks with high speed and efficiency.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet ...

Most mills used in mining rely on impact to breakdown rock to a suitable size for downstream processing. The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grind...

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Sand Ball Mill is the key equipment for crushing the material after it is broken. Ball mill is widely used in cement, Portland products, new building material, refractory material, fertilizer, black and .

offers 986 silica sand grinding mill products. About 85% of these are mine mill, 1% are other nonmetallic minerals products, and 1% are abrasives. A wide variety of silica sand grinding mill options are available to you,

The Sand Mills are mainly used by coating, ink and paint industries for the size reduction and dispersing of pigments in the liquids. The pigment particles are dispersed up to 2 microns in a single pass. The milling chamber is fitted with grinding media, where the feed is pumped from the bottom chamber.

WhatsApp)

WhatsApp)