chocolate ball milling machine, chocolate ball mill ...

The Chocolate Ball Mill is designed for the purpose of finely milling chocolate mass and its admixture.

WhatsApp)

WhatsApp)

The Chocolate Ball Mill is designed for the purpose of finely milling chocolate mass and its admixture.

Mar 31, 2018· The milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain. Click HERE to subscribe to Make i...

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today''s global markets, expanding mining groups are trying

ball charging systems Tonnes of grinding media, normally in the form of steel balls, are consumed by all process plants having mills as part of their comminution process.

Ball Mill Lubrication. Many mines or electric generating stations require raw minerals to be ground and pulverized for final processing. This process can be achieved through one of the different types of ball mills used – SAG Mill‚ Ball Mill‚ Rod Mill and Double Ended Ball Mill included.

intermediate size ready for final grinding in a ball mill, pebble mill, or VERTIMILLTM. Wet grinding is accomplished in a slurry of 50 to 80 percent solids. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Calculating a grinding circuit''s circulating loads based on Screen Analysis of its slurries. Compared to %Solids or Density based Circulating load equations, a more precise method of determining grinding circuit tonnages uses the screen size distributions of the pulps instead of the dilution ratios. Pulp samples collected around the ball mill or rod mill and hydrocyclones, screen or ...

Grinding ball manufacturer,we supply best cast steel balls/mill balls,including high chrome steel balls and ball mill balls,cylpebs for cement,mining and power station. ... Automatic Grinding Ball Molding Line Read more. Chrome Grinding Media Mill Ball Casting Line ZQJX840F4 ... grinding ball heat treatment furnace and grinding ball mold are ...

Overview on the grinding mills and their dual pinion mill drives Figure 3 The 24'' x '' ball 4, 5 and 6 include the technical data for the Copper Mountain ball 4 general ball mill

A comparison of wear rates of ball mill grinding Journal of Mining and Metallurgy, 52 A (1) (2016 ) 1 10 # Corresponding author :

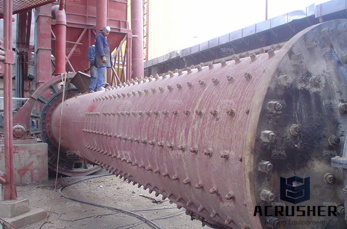

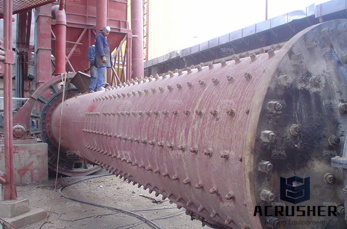

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Automatic Ball Loaders For Ball Mills Pdf automatic ball loaders for ball mills pdf China ball mill machine manufacturers select 2019 high quality ball mill machine products in best price from certified chinese mill equipment manufacturers grinding mill suppliers wholesalers and factory on.

A wide variety of ball lapping machine options are available to you, There are 700 suppliers who sells ball lapping machine on, mainly located in Asia. The top countries of suppliers are China, India, from which the percentage of ball lapping machine supply is 99%, 1% respectively.

China Ball Mill Machine manufacturers Select 2020 high quality Ball Mill Machine products in best price from certified Chinese Mill Equipment manufacturers, Grinding Mill suppliers, wholesalers and factory on

Jul 17, 2014· Ball mills are widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, and the like. Ball mills are also used for ore dressing of both ferrous and nonferrous metals. A ball mill is capable of grinding various ores and other materials either wet .

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

advantages disadvantages ball mill pdf. ... Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new .

Ball Mill Vertimill® SMD 100000 10000 1000 Microns 100 10 1 Mill Ty pe Typical Grinding Ranges Ball Mills and stirred mills are applied across a wide range of applications, but for each ore there is optimum efficient range. The figure to the left shows the typical application ranges for ball mills and stirred mill. The Vertimill is always more ...

Equipment Specification for the Demonstration Units in Zimbabwe Miners prefer milling centers with stamp mills, as they believe that ball mills retain part of the gold in the internal liners. The lack of gold liberation is an evident ...

The small and used ball milling equipment are reliable and qualified. Gusu chocolate machinery, as the manufacturer, supplier and factory of ball mill refiner, will always provide the durable and automatic chocolate ball mill line, chocolate ball milling machine and equipment.

Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

Union Process manufactures a broad line of particle size reduction equipment such as wet and dry grinding Attritors and small media mills, in laboratory and production sizes. Our particle size reduction equipment is customizable to meet your specific milling and dispersion needs.

Mechanical equipment including the plants which are related to produce casting/hot rolling grinding balls, ball mill balls, like casting production line for balls; electrical and gas type heat treatment plant (quenching, tempering, annealing); induction melting furnace; balls charging machine and equipment which is welcomed in mines, balls charging m achine.

WhatsApp)

WhatsApp)