cement industry ball mill wieght

Cement Mill GreatWall Machinery. Cement ball mill is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in...

WhatsApp)

WhatsApp)

Cement Mill GreatWall Machinery. Cement ball mill is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in...

Mar 26, 2013· Ball mill for sale,ball mill price,ball mills – Grinding Mill . Ball mill is widely used for cement, silicate products, new building material, fireproof material, . Weight of ball (t) Size of feed opening (mm) size of outputting

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case".

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder. ... one jar at a time on that unit. That single jar, loaded with lead milling media, and material to be milled, will weigh 6 pounds, which is the weight the doublejar unit''s motor is rated for. ... Barricade the mill with sandbags or concrete blocks ...

How can one select ball size in ball milling and how much material should be taken in mill pot? ... As a thumb rule powder to be milled should be taken as 25% of total ball weight. If the quantity ...

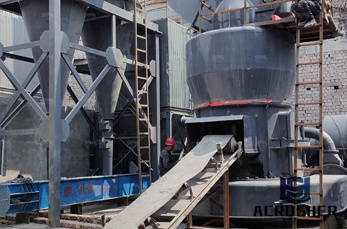

CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 1520% after transformation. The cement ball mill can perform dry process production and also wet process production, moreover it can do grinding and drying at the same time.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball Mill Great Wall Crusher The weight of edgedriving ball mill does not include grinding body''s ; the weight of centerdriving ball mill does not include grinding body''s and driving system''s. GCF Products Mill Heads and Trunnions 2 part mill head metre dia. PROJECT: Boddington Gold MATERIAL: AS .

Ball mill for sale,ball mill price,ball mills – Grinding Mill . Ball mill is widely used for cement, silicate products, new building material, fireproof material, . Weight of ball .

Request for feedback for a Two Chamber Cement Mill Ball Charge and Longitudinal Sieve Analysis. I am looking to get feedback for the following cement mill for a white cement plant. The first compartment has lifting liners and the second compartment has lifting at the beginning followed by classifying liner. The mill dimension is as follows:

Ball Mill, Ball Milling, Ball Mill Price, Cement Ball Mill. Ball Mill From China . This page is about the Ball Mill for silicate, cement, ceramic,chemical fertilizer. If .

Cement ball mill in the process of production and processing has high grinding efficiency, large output, and compared with the general ball mill, this ball mill can save more energy consumption. Our company can design and manufacture a special cement ball mill to meet the actual needs of users according to the output and fineness requirements ...

Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry. Working principle: Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and ...

In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder.

industrycement industry ball mill wieght. cement industry ball mill wieght cement industry ball mill wieght Cement mill Wikipedia A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more ...

In this work the relation between the change in mill output and cement fineness caused in the ball mill grinding process of composite cement with respect to different operating input parameters ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement ball mill is commonly used crushing equipment in the industry,the statistics on the output of the ball mill in actual production is an important basis for the reporttype statistics of the production workshop. The data is mainly the statistics of the production of different shifts and the output of the ball mill, and we usually calculate the capacity of the mill.

Mar 03, 2015· Working principle of Ball Mill /ball cement milling machinery plant Group ... and the time how long the Ball Mill runs. Our Ball Mills .

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

China Ball Mill manufacturers Select 2020 high quality Ball Mill products in best price from certified Chinese Plastic Machinery manufacturers, Milling Machine suppliers, wholesalers and factory on Madein .

Apr 11, 2017· In this article, we will consider the technique for determining the grinding balls bulk weight in fully unloaded mill. This method used in the mills repair (armor plates replacement). The grinding balls unload from the mill into a special pit (needs to open hatches and pour the grinding balls from the drum during mill scroll).

weight of ball in ball mill. weight of ball in ball mill. The grate ball mill is usually used in the first segment of the two stages, or place of disch shaft neck from the material feeding device he cylinder are loaded certain weight of ball. and clinker in Cement Ball Crush Mill exporters, Ball Crush Mill suppliers. weight ...

PORTLAND CEMENT (PC ) QUALITY AT THE BALL MILL A Thesis Submitted to ... response variable was weight percentage of product residue on 32micrometer sieve (or fineness), while the input parameters were revolution percent, falofon percentage, and the elevator amperage (amps), which exhibits elevator charge to the separator.

WhatsApp)

WhatsApp)