Quartz Vein Gold Beneficiation Process JXSC Machine

The quartz vein type gold deposits account for more than 50% of the total gold deposits and gold reserves, are important gold resource. read more quartz vein gold beneficiation process.

WhatsApp)

WhatsApp)

The quartz vein type gold deposits account for more than 50% of the total gold deposits and gold reserves, are important gold resource. read more quartz vein gold beneficiation process.

The gold cyanidation/leaching process is the most versatile processing technique . Process from Complex Ore of Shoughur area Chitral, Kyber Pakhtunkhwa Pakistan process includes the basic mineral processing. Live Chat. Gold Beneficiation Multotec. Flotation screens are used in the gold beneficiation process to isolate copper particles to ...

This post mainly introduces the comparison between the flotation gold extraction process and gold cyanidation process. Gold flotation process is a common metal ore beneficiation process, and is also applicable to gold mines. This kind of gold extraction process is mainly suitable for sulfide goldbearing quartz vein ore, polymetallic gold ...

Overall, the cyanide process is very efficient. A gold ore containing less than one gram of gold per ton can, in some cases (and depending on the gold price), be profitably treated. A modern cyanide mill recovers or extracts 95% to 98% of the gold in the ore. In a cyanide mill, lime and cyanide are added to the ore pulp in the grinding circuit.

ore beneficiation gold cyanidation process low consumption. Flotation and cyanidation of a semi refractory gold ore. Beneficiation of a low grade gold ore was studied by column flotation. . study indicated the reduction in cyanide consumption with high grade gold concentrates . Cyanidation is the main process used worldwide for the extraction ...

beneficiation of gold process ellulnl gold beneficiation process with large capacity in united stat the mineralogy determines the recovery process of gold leaching is a hydrometallurgical method that permits the beneficiation of gold ores from deposits for Get Price [24/7 online] Beneficiation Process Of Gold Ore mirestcz

The Cyanidation Process or CYANIDE LEACHING is ''most notably used in the recovery of gold. Safety and environmental concerns are of prime importance in the operation of a cyanidation plant. As we get farther into this type of recovery you will see why. The preparation of the ore for processing is similar to flotation. The ore must be ground to a specific size before it can be treated.

Gold Beneficiation Process Cyanide greenrevolution. Cyanide Leaching Of Gold Mine information on cyanide leaching of gold leach plants. the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metal. process and the other is the adsorption of the gold onto activated carbon.

Gold Beneficiation. Gold beneficiation solutions from Multotec covers each stage of the beneficiation process, from ROM stockpile to processed mineral and tailings.. As a technologydriven company, our gold beneficiation solutions are supported by a team of skilled engineers and metallurgists, with a wealth of process and application knowledge that we use to achieve gold beneficiation at the ...

Gold Ore Beneficiation Plant. The worth of mining gold is known as source of economics and economic value in the jewelry industry as well as in high level electronics and highly profitable. Gold ore beneficiation is a processing to get gold out of ores. At the gold ore beneficiation plant, gold should be extracted from the ore.

The process of cyanide leaching is mainly used where the earth has a high gold concentration making an industrial development worthwhile. For this process the goldbearing rock is crushed to sand and dust. Subsequently, the rock dust – piled in heaps, columns or stored in tanks – is combined with a sodium cyanide solution (sodium salt of

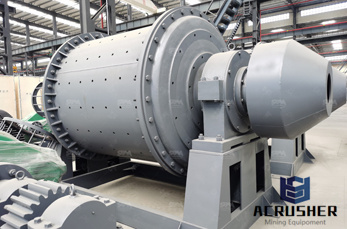

refractory gold is readily accessible for cyanide leaching. There are several variations of comminution circuits used in the gold industry, such as: Multistage crushing and pebble and/or ball milling circuits, typical of older installations. The process design of gold leaching and carboninpulp .

This paper has reported the beneficiation and characterization of gold from Itagunmodi gold ore in Atakumosa West LGA in the State of Osun Nigeria using cyanide solution obtained from cassava and commercially available sodium cyanide analar grade. Cyanide solution extracted from cassava variety TMS 30572 leaves obtained from Obafemi Awolowo University () Research and Teaching Farm .

Jul 25, 2016· The successful appliion of heap leaching to the extraction of gold from low, grade deposits has been one of the main factors in higher Ore Cyanidation Processing Gold Cyanidation Beneficiation ore ...

Aug 03, 2019· Lime is a lowcost item that is widely used in gold beneficiation plants. The following is a systematic description of lime properties, its role in flotation, cyanidation, amalgamation and other mining operations, for your reference.

Oct 20, 2014· Leaching gold with a cyanide solution remains the most widely used hydrometallurgical process for the extraction of gold from ores and concentrates. Despite the difficulties and hazards of working with cyanide, no other process has yet been proven to be an economic viable alternative.

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Cyanide Leaching Of Gold Mine information on cyanide leaching of gold leach plants. ... the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metal. ... process and the other is the adsorption of the gold onto activated carbon.

Taking the gold cyanidation plant with processing capacity of 100000 tons and gold grade of g/t as an example, gold CIL process can save the investment cost of 486000 than the CIP process, reduce the capital backlog of 201700, save and recycle capital of 675100 in advance excluding the cost of activated carbon. 2.

Cyanide is a lixiviant, or reagent that is used to leach, often in tanks, gold from a solid matrix and form a gold cyanide complex. The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon. CIL stands for carboninleach. This is a gold extraction process called cyanidation where carbon is added to ...

Gold Cyanide Solution (Leaching Gold With Cyanide) Since the 1890''s, cyanide has been used to recover gold from gold bearing ores. And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metal.

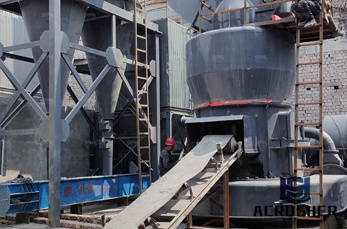

Dec 20, 2018· Under the 400 mesh condition, the gold leaching rate increased by 8%. If the tower grinding machine is used to implement the edge grinding and immersion process in gold mines, it will be a major innovation in the cyanide gold extraction process. The cyanide gold extraction process also suits for copper leaching, zinc leaching, sliver leaching, etc.

Jul 31, 2019· Gold ore has high mining value. From a certain perspective, gold ore beneficiation is one of the most selective and most complex types of mineral processing. Here are 10 kinds of gold processing flow design, mercury amalgamation, heap leaching, cyanide process, gravity .

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination is the most commonly used leaching process for gold extraction.. Production of reagents for mineral processing to recover gold, copper, zinc and silver represents ...

WhatsApp)

WhatsApp)