Cement kiln Wikipedia

Vertical shaft kiln (VSK) for Dolomite. Single shaft type, high performance and mix fire kiln system from kinc adds enormous advantages to lime | dolomite and economic way for lime and dolomite calcinations.

WhatsApp)

WhatsApp)

Vertical shaft kiln (VSK) for Dolomite. Single shaft type, high performance and mix fire kiln system from kinc adds enormous advantages to lime | dolomite and economic way for lime and dolomite calcinations.

Energy optimisation of vertical shaft kiln operation in the process of dolomite calcination ... compare the advantages of modern shaft kilns with other ... The cement industry contributes about 5% ...

Chaeng can offer Vertical Shaft Kiln(vsk) Cement Plant from100 TPD to 300 TPD on turnkey basis. Vertical shaft kiln technology is approved by National Council of building material and Cement Kiln is modern day answer for cost effective production and a boon for the developing countries. VSK is only technology available world wide for small ...

Vertical shaft kiln (vsk) for Lime Single shaft type, high performance and mix fire kiln system from Kiln adds enormous advantages to lime | dolomite industry. Effective and economic way for lime and dolomite calcinations Equipped with external burners and inside special refractory structures, that allow a homogeneous heat distribution in all ...

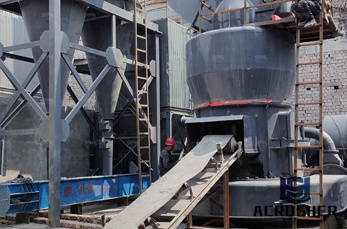

Vertical Shaft Kiln is used for the calcination of cement clinker, limestone, bauxite and other materials. The vertical kiln manufactured by ZK group has the advantages, such as modern design, new technology, environmental protection,energy saving, higher machanization and automaticity etc. We offer 50 TPD to 300 TPD vertical shaft kiln on turnkey basis for cement and active lime plant, which ...

Cement Plant Machinery ; VSK Portland Cement Plants. VRRK Cement Plants. Clinker Grinding Units. Rotary Kiln Plants. Cement Plant R and D. Pozzolana Making Plant. Synthetic Gypsum Plant. Vertical Shaft Kiln For Cement Plant. Plant Installation Turnkey Project. Chemical Plants. Ferric And NonFerric Alum Plant; Sulphuric Acid Plant; Npk Npks Mix ...

Vertical Shaft Kilns. We are manufacturers, suppliers and exporters of Vertical Shaft Kiln. Application : Clinker, Lime stone, Minerals. Vertical Shaft Kiln technology. Continuous process allowable temperature up to 1500 Degree. Subdrive through Vertical Mounted Gear Box. Subdivided in .

There are two main types of kilns to produce cement: the Vertical Shaft Kiln and the Rotary Kiln. The Vertical Shaft Kiln or VSK is probably the first type of kiln that was used and it can be traced back to the 5th century in Greece, when they were used for limestone calcining (Reiter, AC, 11/1997, p. 23).

VSK Cement Plants. Chanderpur Works Pvt. Ltd. is offering Vertical Shaft Kiln Cement Plant from 50 TPD to 300 TPD on turnkey basis. Vertical shaft kiln technology is approved by National Council of building material (Govt. of India) and Cement Shaft Kiln is modern day answer for cost effective production and a boon for the developing countries.

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two. The axis is inclined at a slight angle, the end with the burner being lower.

vertical shaft lime kiln designer . Vertical Shaft Lime KilnGrinding PlantProductHenan ... This vertical shaft lime kiln design adopt the fully automatic mechanization vertical kiln to produce active lime, suitable for the lime production project with single kiln within the scale betweent/d, and it can also combine multi kilns.

Jul 02, 2008· CLINKER FROM ROTARY OR VERTICAL SHAFT KILN. Dear Sirs, what is the difference between a clinker produced in a rotary kiln and the clinker produced in a vertical shaft kiln? I know that the disadvantages of the VSK kiln are the inclusion of ash in the clinker, the problem with homogeneity of heat distribution, the low production.

advantages of vertical shaft kiln cement plant pakistan. history of vertical rotary ciln for cement plant, offers some insight into maintaining rotary kilns in a cement plant, and the vertical, cement: the Vertical Shaft Kiln and the Rotary, in pakistan; rock . INTERNATIONAL INDUSTRIAL MARKETS,

Protechglobal Consulting Services offers Vertical Shaft Kiln (VSBK) cement plants from 100 TPD to 600 TPD on turnkey basis. Vertical shaft brick kiln technology is adopted by customers for projects of smaller capacity for its low cost implementation.

Manufacture of cement by vertical shaft kiln technology: Large big cement plants with large capital investment use rotary kiln technology but certain cement plant use vertical shaft kiln technology of long horizontal kilns used in dry and wet process. In VSK technology, pellets of raw material are made by pan nebuliser or palletise.

advantages of vertical shaft kiln cement plant pakistan. cement plant projects are being considered, but the first one to begin operation will Twosupport kiln 525x62 m (5,500 tonnes per day) the vertical roller mill has the flexibility to handle these sign will still take advantage of semi shaft kiln manufactured Portland and other DG Khan is the first plant in Pakistan to Get Price [email ...

Jul 11, 2018· Vertical kiln / shaft kiln operation principle,we can supply TPD Vertical kiln / shaft kiln and rotary kiln for you . Whatsapp:+ Email...

offers 4,643 vertical cement kiln products. About 96% of these are cement making machinery, 1% are industrial furnace. A wide variety of vertical cement kiln options are available to you, such as free samples.

Ashoka Group offering Vertical shaft kiln cement plants high efficiency, cost effective, energysaving Cement plants based on VSK technology designed and developed by our efficient and dedicated team of various individuals.

Overview of cement production process of vertical kiln. Normally in the process of cement production, cement plant is through the rotary kiln and the shaft kiln cement production in two ways, rotary kiln, as the name implies, its essence is the use of the horizontal cylinder rotary type cement clinker calcining equipment in cement production ...

Selecting the Proper Lime Kiln Technology. Lime is a key industrial mineral used as a chemical additive by many industries. The industrial facilities that utilize Lime in various forms are metal ore processing, metallurgy, steel, paper, pharmaceuticals, sulfur removal, and water treatment.

Constant sharp rotary kiln is continuous operation, production, quality and labor productivity than the ordinary shaft to the policy requirements of the Building Materials, a small cement plant application mechanized vertical kiln, gradually replacing the ordinary shaft kiln.

Shaft kilns Question 2. The NCB (National Council for Cement Building Materials) in India publishes a number of Technology Digests, Monographs Research Bulletins. At least 10 of these relate to vertical shaft kiln technology. Unfortunately I can''t tell you which is the best.

Our standard linings for vertical shaft kilns consist of wearresistant hotface linings and thermally efficient backup linings. This combination provides lime producers with an economical and tough refractory lining that can withstand the thermal and mechanical challenges present in a vertical shaft kiln.

WhatsApp)

WhatsApp)