Gears and Pinions

Gears and Pinions. is proud to announce the launch of our new rebranded offer: Gears and Pinions. A complete range of gear and pinion sets, inspections, design, installation and alignment services to drive your mill''s performance.

WhatsApp)

WhatsApp)

Gears and Pinions. is proud to announce the launch of our new rebranded offer: Gears and Pinions. A complete range of gear and pinion sets, inspections, design, installation and alignment services to drive your mill''s performance.

Motor Power/Media Addition The power drawn by the Vertimill motor is required to establish the grinding rate. Motor power should be measured using corrected power. Monitoring mill motor amperage is not an accurate method. As the grinding media wears fine enough to be carried out by the uprising velocity in the mill, the

cement grinding mill motors 100 hp. ball mill drive motor choices Artec Machine Systems. ball mills, the starting torque restrictions of some of the newer mill drive ... This study began with a decision by The Monarch Cement Company to add a new ... Drive 2 A 5000 HP, 514 rpm synchronous motor with an air clutch and gear box to a .... .

Grinding mills and synchronous motors D''Angelo International. Grinding mills and synchronous motors. 13 ft diameter Allis Chalmers Ball or SAG Mill. Description: 13 ft diameter Allis Chalmers grinding mill configurable as ball or SAG mill – Shell cut into multiple sections for transport, ...

selection and evaluation of grinding mill motors and d rives. Grinding is the required powdering or pulverizing process when final size of below 2 mm is needed. SAM can provide the proper grinding measure to all kinds of methods ...

Standstill detection – Prevents the motors from restarting if the mill is still rocking or moving after a stop command. Softstarting – Smoothly starts the mill without mechanical shocks and limits the current drawn from the network, avoiding unexpected downtime due to voltage unbalances.

Evaluation of synchronous motors on grinding mills article{Seggewiss2014EvaluationOS, title={Evaluation of synchronous motors on grinding mills}, author={George Seggewiss and Jingya Dai and Mark Fanslow}, journal={2014 IEEEIAS/PCA Cement .

the right type of mill, how to operate your mill efficiently, and how to maintain your mill. There are numerous types of grinding mills. This article focuses on two widely used types: the hammer mill and the jet mill. Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from

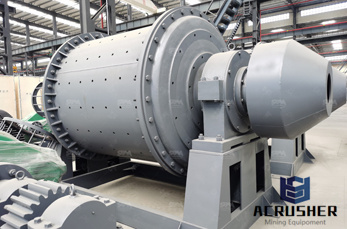

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc. The applications of ball mills are ubiquitous in mineral

Jun 11, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Evaluation of synchronous motors on grinding mills Abstract: Synchronous motors continue to be a viable alternative to induction motors because of efficiency advantages. Long used for providing leading kVARs for PF improvement and helping with the device switching in Load Commutated Inverter (LCI) drives, these machines are efficient prime ...

Selecting Inching Drives for Mill and Kiln Applications Glen Cala Frank C Uherek, Principal Engineer Gear Engineering Software Development Abstract The inching drive, also known as a barring or auxiliary drive, is an important component of any mill or kiln installation. .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Manual grain mills have the rather obvious benefit of not requiring a power source, so they''ll work in locations without power or during blackouts. For those who plan to mill when camping or doing other outdoor activities, a hand crank mill is a great option. Although manual mills require a great deal of elbow grease, some users prefer the ...

This equals more confidence in your grain mill and almost no warranty work for us, we both win. The new style WonderMill with it''s LG motor is now so powerful that if the power turns off during the milling process, it can be turned back on and continue grinding as if nothing had interrupted the milling process (see video to the right).

Abstract: An understanding of torque relationships in the operation of rotary grinding mills necessitates a complete analysis of the mill, gear train, and drive motor insofar as torsional load, inertia, and frictional losses are concerned. Ability of a drive motor to develop the required torque is dependent upon its inherent torque characteristics in combination with its electrical supply system.

Our GMD eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings: By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor.

New and Used Ore Processing and Grinding Mills for Sale Savona Equipment is an ore processing and grinding mills supplier worldwide. We supply grinding mills for primary ore processing plants through to secondary and tertiary ore processing facilities. We buy, sell and consign grinding mills of all leading suppliers including , FL, CITIC, Polysius, ABB Ltd, Polysius, Koppern and ...

behavior of large Ring Motors for grinding mills 3 1 Introduction The mining industry uses grinding mills to comminute tonnage. Large grinding mills are driven by Gearless Drives, with the Ring Motor as its main component. The Ring Motor is wrapped around the mill and its rotor poles installed at an extension of the mill head.

The time has come to rethink our approach to mill drive motors because of the growth in size of newer ball mills, the starting torque restrictions of some of the newer mill drive configurations, and the softness of some utility services. This paper looks at the serviceability and economics of five different mill motor

Ring gear drives huge grinding mill. By this summer, a grinding mill that is bigger around than a Boeing 747 will turn chunks of copper ore into gravelsized bits for smelting and refining ...

The Mortar Grinder RM 200 can mix and homogenize powders, suspension and pastes, even for samples with high viscosity. The RM 200 is suitable for the proper and reproducible sample preparation to analytical fineness. The sample grinder substitutes cumbersome hand mortars by a high performance drive with electronic control. The grinding set can be cooled and heated and is very easy to clean.

» selection and evaluation of grinding mill motors and drives » what coal mill, vertical roller mill, ... » details of automatic grinding mill motors >>TYY LXP. Rio Super Automatic Espresso Grinder Whole Latte Love. Feature Details. The Rio Super Automatic Grinder provides a large range of grind settings so it is adaptable to ...

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its applications. The Attritor is a grinding mill containing internally agitated media. It has been generically referred to as a "stirred ball mill."

WhatsApp)

WhatsApp)